At Omniplast Private Limited, we specialize in advanced multi layer laminates designed for diverse food and FMCG packaging needs. Our two layer laminates made from PET, PE, BOPP, and CPP offer strength, flexibility, and freshness, ideal for snacks, wheat flour, and rice. For higher barrier and seal strength, our three layer laminates with PET, PE, BOPP, CPP, and Met PET structures ensure superior protection and longer shelf life for namkeens, shampoos, mehndi, and other premium products. solutions.

Pushing innovation further, our four-layer extrusion laminates use molten resin technology to minimize WVTR and OTR, preserving hygroscopic foods and snacks with excellence. Every structure is custom-engineered for function and aesthetics delivering reliable, durable, and distinctive packaging

We specialize in manufacturing custom preformed pouches tailored to a wide range of product and brand requirements. Each pouch is designed with a focus on both aesthetic appeal and functional performance, offering exceptional durability and product protection. Our diverse range includes stand up pouches (with or without zippers), side gusset pouches, eyelet and loop handle pouches, and other innovative formats crafted to enhance convenience and shelf presence.

Every pouch is produced entirely in house, ensuring end to end control over quality, consistency, and precision. By combining advanced materials, modern technology, and years of expertise, we deliver packaging solutions that not only preserve freshness but also strengthen brand identity and consumer trust.

Before production begins, we meticulously inspect all incoming raw materials to ensure they meet our strict quality criteria. This includes assessing material composition, durability, and compliance with relevant regulations.

Throughout the manufacturing process, our skilled technicians conduct regular inspections and tests to monitor key parameters such as thickness, dimensions, and visual appearance. Any deviations from specifications are promptly addressed to maintain product consistency.

Once the packaging is fabricated, it undergoes a series of comprehensive quality assurance checks. These include visual inspections, dimensional measurements, and functional tests to verify performance and durability

In addition to visual and dimensional checks, we conduct rigorous performance testing to evaluate the packaging’s ability to protect and preserve its contents. This may include drop tests, compression tests, and environmental simulation to simulate real-world conditions.

Each batch of packaging produced at Omniplast is meticulously tracked and documented throughout the production process. This ensures full traceability and allows us to quickly address any issues that may arise.

We are dedicated to continuous improvement in our quality control processes. By regularly reviewing and refining our procedures, we strive to enhance efficiency, consistency, and overall product quality.

The manufacturing setup houses the most advanced packaging technologies with forced draft ventilation systems and ‘Good manufacturing practices’ in place.

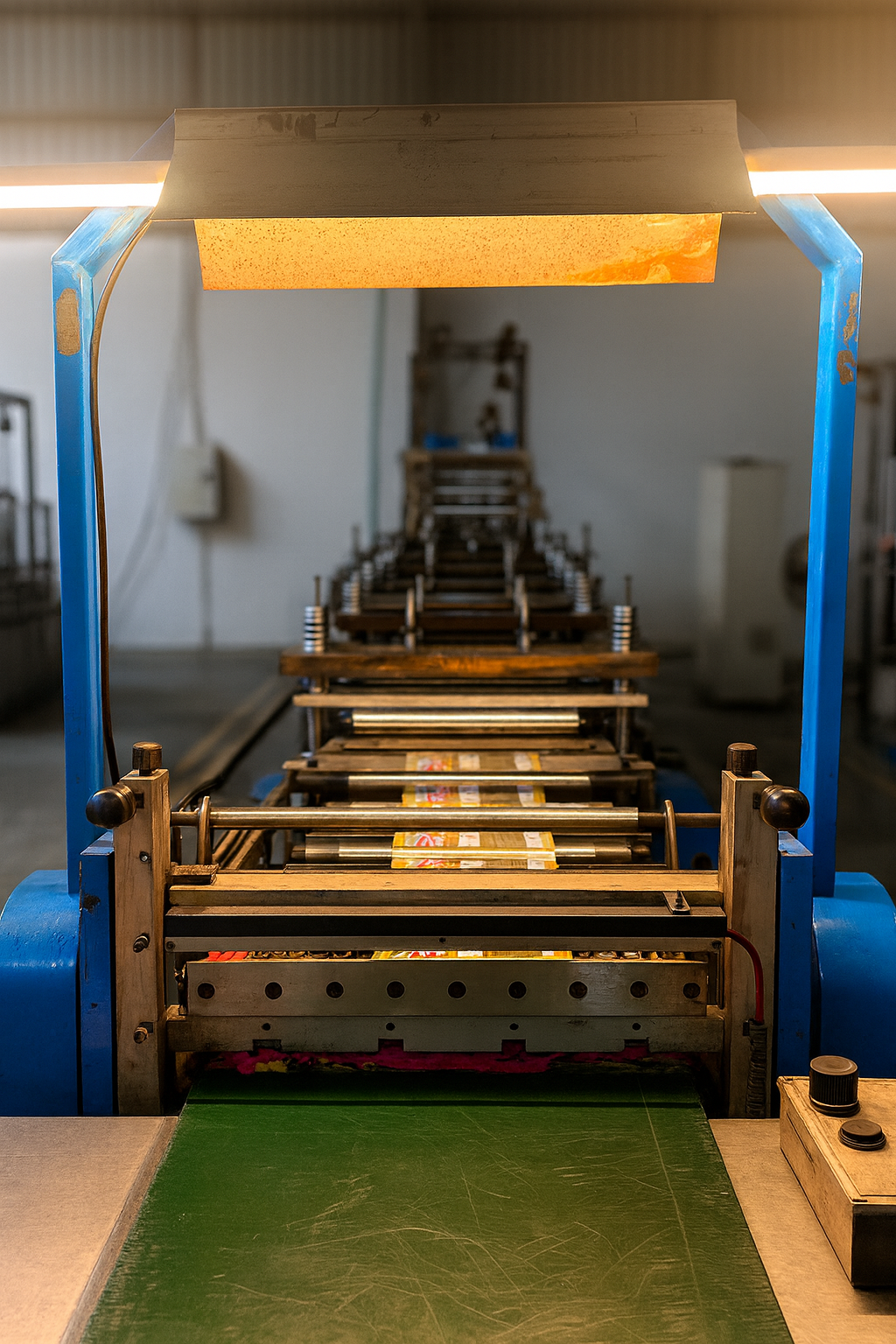

High-speed web inspection rewinding machines with web guides and online stroboscopes to segregate any distorted printed materials.

An inspection and rewinding machine used to rectify segregated, slitted rolls that require re-jointing/ flush winding.

Copyright © 2026 Omni Plast | Designed by : Digital Dynamics